Designed with all considerations of ISO13320 our entire product range is fit for most requirements of the process engineer.

As well as the particle size measuring modules, we supply all the sampling systems required to take the sample out of the process, and where required, to put it back into the process. This means in many cases, process particle size can be measured in real time with zero product loss.

Whether you are interested in measuring air conveyed particulates(dry), or particles in liquid suspension(wet), we have products to suit.

ISO 13320 states that laser diffraction can measure particles in the range of 0.1 to 3000 microns, and we can offer measuring systems to cover that entire range. However, as with any technique, when the limits of the range are approached, the applicability of the measurement becomes more questionable, from 0.1 to 1100 microns wet, and 0.5 to 1100 microns dry. Please contact us for applications which fall outside this range.

Our standard product range can be divided into 2 main categories:

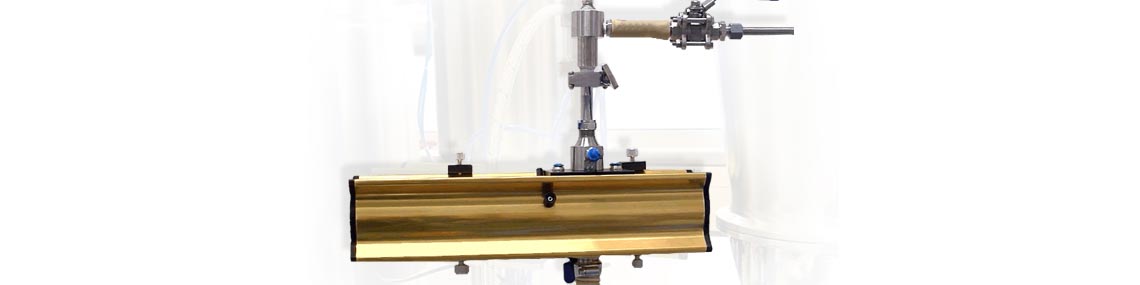

Measurement of abrasive products

Where the materials produced are abrasives, then clearly the lifetime of any apparatus which comes into contact with that material will need to be considered. Xoptix have developed a range of ceramic lined components for their systems which typically extend the life of these parts from several months to several years. Typical applications are Minerals, Cement, Silica. All these parts are interchangeable with the standard parts.